3D printing is the process of taking designs created using computer-aided design (CAD) software and turning them into three-dimensional objects made of plastic, typically PLA. PLA (Polylactic Acid) is a raw material used to create 3D models and is one of the most popular 3D printing materials (known as filaments) around.

It is important to note that the purpose of our 3D printer is to promote and foster creativity and knowledge, therefore we cannot guarantee that objects printed will be of commercial quality. If patrons need something to be extremely precise, they may consider using a commercial printer.

3D Printer Basics

- This service is available to FRVPLD cardholders. Plan ahead, as it takes one to three weeks to create your object.

- Objects must be submitted in the .STL or .OJB formats. Maximum print dimensions are 8.3 (L) x 8.3 (W) x 9.84 (H) inches.

- 3D prints are $.10 per gram, but we'll be sure to notify you of the approximate print cost once we receive your request.

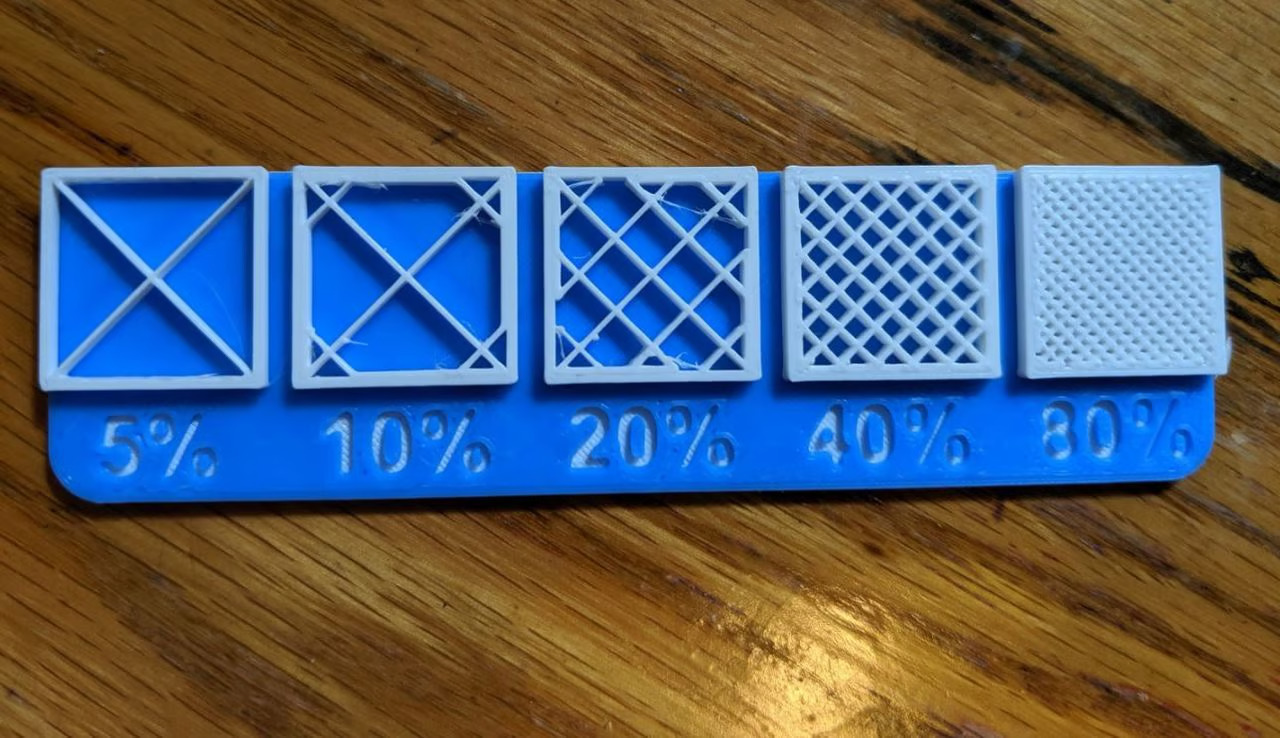

- Unless otherwise specified, a 3D model will be printed in 0.20mm layer height with a 10% infill.

The Fox River Valley Public Library District has a Prusa i3 MK3S+ and primarily uses PLA (polylactic acid) plastic, known as filament, to create objects. PLA filament is a bioplastic that is derived from corn and contains no heavy metals, phthalates or BPA. Once a design is sent to the printer, the printer feeds the filament through an extruder with a metal nozzle on the end. The extruder heats up to 215 degrees Celsius (419 degrees Fahrenheit) and extrudes the filament onto a metal sheet heated to 60 degrees celsius (140 degrees Fahrenheit) in sheets, layer-by-layer. As these sheets cool they bind together to create an object.

Objects created with the 3D printer can range from completely hollow (known as Vase Mode) to completely solid as determined by the quality settings input into the printer. Higher quality prints use much more filament than lower quality prints.

Patrons are permitted to use the library’s 3D printer to create objects that comply with local, state and federal law as well as all other library policies. Patrons may not create objects that are:

- Dangerous or pose a threat to others. (Guns, knives, parts for weapons, etc.)

- Sexually explicit, obscene, or inappropriate for the Library environment

- A violation of the MakerBot Replicator terms of use

- Copyrighted or otherwise protected by a patent or trademark

- For commercial use

All submitted designs are subject to review by library staff. Designs may be rejected if they are not capable of production. If this is the case, the patron will be informed by email or telephone of the problem(s) and change(s) needed to make the design printable.

The Fox River Valley Public Library District has a variety of colors available to choose from and is always adding more to the selection; check back often for new color choices!

We are happy to print your designs, but only designated, trained library staff will be able to print objects. Demonstrations will be provided to the public to showcase the 3D printer.

Layer height is a measurement of how much material the printer’s nozzle extrudes for each layer of your part. It’s measured in microns or millimeters, can be adjusted through a slicer program, and varies from project to project.

If a design is artistic, highly detailed, or must be incredibly precise, a lower layer height should be used such as 0.15mm down to 0.07mm. However, be wary of using thin layers as these increase printing time and use more filament.

On the other hand, if patrons need to print a part quickly, keep costs low, or are prioritizing function over aesthetics, a larger nozzle and a taller layer height can be used such as 0.25mm or 0.30mm. A taller layer height means the printer has fewer layers to print to achieve the same volume, which speeds up the printing process and gives a fully functional product at a lower cost. However, the part will also have fewer details and lower quality overall.

Infill density is the “fullness” of the inside of a part. In slicers, this is usually defined as a percentage between 0 and 100, with 0% making a part hollow and 100%, completely solid; this greatly impacts a part’s weight. The fuller the interior of a part, the heavier it is resulting in more filament used. Besides weight, print time, material consumption, and buoyancy are also impacted by infill density.

FRVPLD provides learning opportunities by offering technology resources to benefit our residents. Our 3D printer accomplishes this by:

-

introducing patrons to manufacturing and engineering as viable career options

-

Empowering patrons to use CAD software to design and create three-dimensional objects that have both practical and fun purposes

-

Engaging patrons in science, technology, engineering and mathematics (STEM)

-

Providing another level of service for our patrons to utilize and enjoy.